How the product works, its components, and benefits.

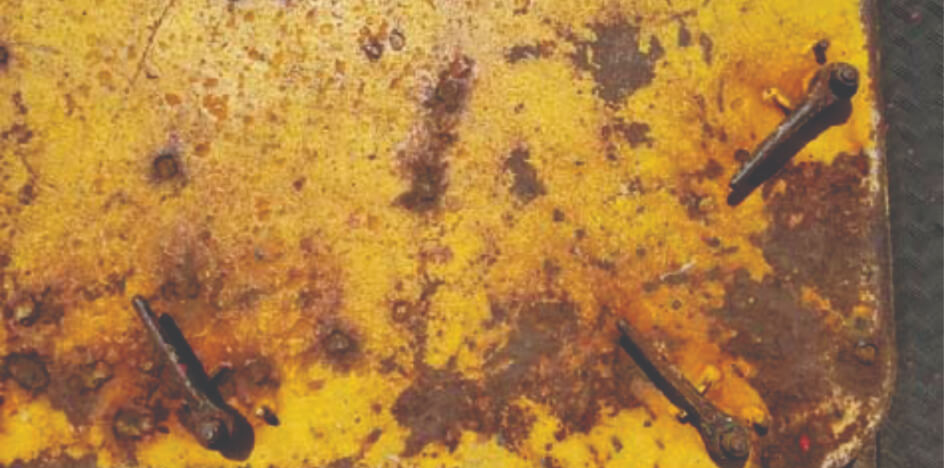

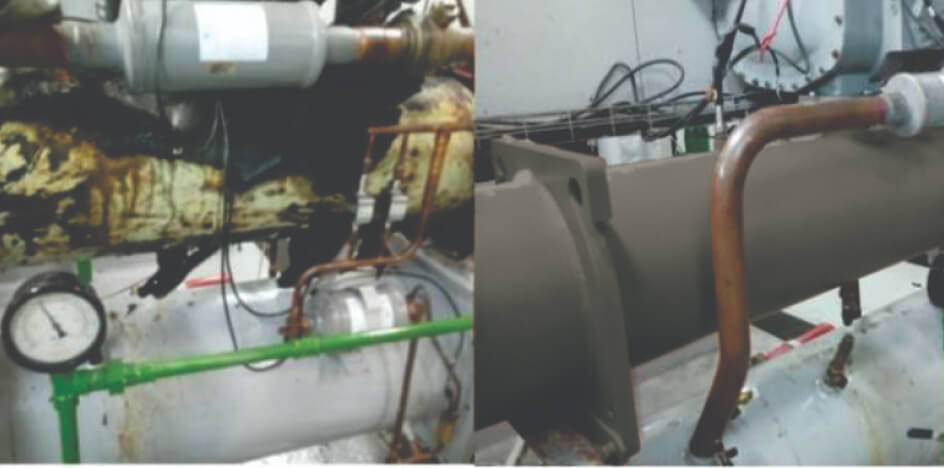

RUST Primer is designed to effectively combat corrosion on rusted metal surfaces. It works through a chemical reaction with either the oxide or the metal itself, creating a robust layer of iron phosphate. This layer is essentially impermeable and highly resistant to corrosion, offering long-lasting protection against adverse environmental effects.

The primary function of RUST Primer is to form a bonded iron phosphate surface on the metal, which not only halts the existing corrosion process but also prevents future rust propagation. This adherent layer not only protects the metallic surface but also promotes excellent adhesion between the base material and any subsequent paint layer, ensuring a durable and high-quality finish.

Additionally, the primer’s elasticity allows it to adapt to temperature variations, from extremely low temperatures (-90ºF / -67ºC) to high temperatures (400ºF / 200ºC), without compromising its effectiveness. This makes RUST Primer particularly suitable for extreme environments where durability and resistance are essential for protection against corrosion and wear.

In summary, RUST Primer not only protects metallic surfaces against initial and future corrosion but also significantly improves the adhesion and durability of subsequent coating layers, providing an effective and reliable solution for maintaining structures and equipment exposed to harsh conditions.

How to Use: Step-by-step application guide.

Proper preparation and standard application of RUST Primer are crucial for ensuring effective corrosion protection on metal surfaces. Here is a detailed guide on how to perform these processes:

Standard Surface Preparation:

- Rust and Loose Paint Removal: Use a wire brush or a water jet to completely remove rust and any traces of loose paint from the surface to be treated.

- Surface Degreasing: Apply a degreasing solvent to eliminate any oil or grease present on the surface. Then, rinse thoroughly with water to remove any solvent residue.

Standard Application of RUST Primer:

- Application Methods: RUST Primer can be applied on damp surfaces using a brush, roller, or spray, offering flexibility in the choice of application method.

- Ideal Application Conditions: Apply the primer at ambient temperatures ranging between 45ºF and 140ºF (7ºC and 60ºC) to ensure proper adhesion and curing.

- Coating Thickness: Apply two layers totaling between 120 and 140 microns, followed by a top coat to maximize corrosion protection.

- Finish Compatibility: RUST Primer is compatible with many existing types of finishes, especially those with low volatile organic compounds (VOC) content, facilitating application in various maintenance or renovation contexts.

- Post-Welding Treatment: Parts coated with RUST Primer can be welded directly. After welding, any loose paint should be removed by brushing or washing, followed by reapplication of paint to restore the surface to its previous condition.

In summary, following these standard preparation and application procedures ensures that RUST Primer works effectively, providing long-lasting corrosion protection on metal surfaces, with the flexibility to apply in various environmental conditions and compatibility with other coatings.

Benefits

List of Advantages:

- Chemically reacts with oxide or steel to form a robust layer of iron phosphate.

- Bonded iron phosphate layer is impermeable and highly resistant to corrosion.

- Excellent adhesion between the base material and the primer layer.

- Protects against lateral corrosion on damaged painted surfaces.

- Elasticity and tolerance to extreme temperatures (-90ºF to 400ºF / -67ºC to 200ºC).

- Can be applied to damp surfaces.

- Dries quickly in the air (30 minutes to the touch, 2 hours for a second coat).

- Reacts with existing paint and corroded steel areas, facilitating maintenance of old painted structures.

- Coated surfaces can be welded directly; after welding, the area can be washed or cleaned with a wire brush and repainted.

- Can be used to recoat galvanized steel, including rusted galvanized structures and oxidized steel.

- Insensitive to salts and chlorides; RUST Primer’s acid neutralizes alkaline chlorides, preventing common failures in conventional painting systems.

How RUST Primer Offers 50% Savings or More:

Conventional Painting:

- Requires abrasive blasting.

- With heavy equipment or toxic chemicals.

RUST Primer:

- High-pressure water washing.

- Paint directly after washing.

How RUST Primer Provides Savings and Performance

RUST Primer is an economical and efficient solution that simplifies the process of protecting metal surfaces with minimal preparation and high effectiveness:

Simplified Preparation: RUST Primer requires minimal surface preparation, functioning as a single-step process. In contrast, conventional coating systems often demand surface preparation that can account for up to 70% or more of the total coating costs. With RUST Primer, this preparation is significantly reduced to about 5% to 15%, resulting in substantial cost savings.

Thickness Savings: Unlike conventional systems, RUST Primer generally requires only half the coating thickness, contributing to further material cost reduction. This lower product consumption not only optimizes resource use but also enhances application efficiency.

Quick Drying: One of the significant advantages of RUST Primer is its rapid air drying between coats, which provides a considerable time-saving during application. This feature reduces waiting times and speeds up the protection process, allowing for a quicker return to normal operation of treated surfaces.

Technical Documents: TDS and SDS Sheets

Below, you will find the TDS (Technical Data Sheet) and SDS (Safety Data Sheet) for Rust Primer. These documents provide detailed information on technical specifications and safety guidelines essential for safe and efficient use.